VisSim: A Comprehensive Overview of the Visual Block Diagram Program for System Simulation and Embedded Design

VisSim, developed by Visual Solutions of Westford, Massachusetts, is a specialized graphical software designed for the simulation of dynamical systems and the model-based design of embedded systems. First introduced in 1989, VisSim has played a critical role in the development of virtual prototypes and embedded systems by leveraging its unique visual programming language. Although initially independent, Visual Solutions was acquired by Altair in 2015, and VisSim was rebranded as solidThinking Embed, a tool within the solidThinking Model-Based Development Suite.

This article provides a detailed exploration of VisSim, including its core features, capabilities, evolution over time, and its role in the modeling of dynamic systems. We will also discuss its interface, functionality, and its use in various industries such as automotive, aerospace, and manufacturing.

What is VisSim?

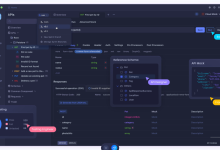

VisSim is primarily a visual block diagram program that facilitates the simulation and modeling of dynamical systems. It allows engineers and designers to create, simulate, and optimize control systems, embedded systems, and other dynamic models without needing to manually write complex code. Using VisSim’s graphical user interface (GUI), users can create models by connecting blocks that represent different components or processes. These blocks correspond to mathematical operations, and the connections between them represent data flow and system interactions.

The program utilizes a data-flow paradigm to represent dynamic systems through block diagrams. The blocks are essentially representations of mathematical equations or physical components, such as integrators, summators, or gain elements. By connecting these blocks, users can visually define the behavior of a system, making the software an invaluable tool for modeling and simulation.

Key Features and Functionality

VisSim offers a range of features that support a variety of system design and simulation tasks. Some of the key capabilities include:

-

Graphical Data Flow Paradigm: The primary feature of VisSim is its graphical data-flow interface, which allows users to model dynamic systems by creating block diagrams. Each block in the diagram represents a mathematical operation or component of the system, and the connections between them define the flow of data.

-

Control System Modeling: VisSim is widely used for the modeling of control systems, including both continuous and discrete systems. The software is particularly popular in industries like automotive, where control systems for engines, transmission, and other subsystems need to be designed and tested.

-

Automatic Code Generation: One of the standout features of VisSim is its ability to convert block diagrams into executable code. The system automatically generates C-code, which can then be compiled and deployed to target embedded systems or hardware platforms. This eliminates the need for manual coding, which can be time-consuming and error-prone.

-

State-Based Modeling: VisSim supports state-based modeling through the inclusion of UML (Unified Modeling Language) state charts. With the introduction of version 8, VisSim became capable of modeling state-based systems, which are crucial for applications such as process plant sequencing, serial protocol decoding, and other systems that involve complex state transitions.

-

Real-Time Simulation: The software allows users to simulate dynamic systems in real time, enabling immediate feedback on how a model behaves under various conditions. This is critical for testing and refining control algorithms before deploying them to hardware.

-

Integration with Hardware: VisSim is designed to seamlessly integrate with hardware platforms, making it ideal for prototyping and testing embedded systems. It supports various embedded targets and is compatible with hardware-in-the-loop (HIL) simulations, which are essential for validating the performance of embedded systems in real-world scenarios.

-

Comprehensive Library of Blocks: VisSim includes a vast library of pre-built blocks, which can be used to represent a wide array of physical and mathematical processes. These blocks cover areas such as signal processing, electrical systems, control systems, mechanical systems, and more.

-

Graphical User Interface: The interface is intuitive and user-friendly, with drag-and-drop functionality for creating block diagrams. This ease of use allows engineers to quickly create models and simulations without needing to write complex scripts or code.

Evolution and Acquisitions

VisSim has undergone several iterations since its release in 1989, evolving alongside advancements in both hardware and software. The key milestone in its history came in 2015 when Visual Solutions was acquired by Altair. Following the acquisition, VisSim was rebranded as solidThinking Embed as part of Altair’s Model-Based Development Suite. This rebranding reflected a broader shift in the industry toward model-based design and simulation tools.

The transition to solidThinking Embed also brought enhancements to the core functionality of VisSim, including improved integration with other design tools, enhanced code generation capabilities, and new features for modeling state-based systems. These updates allowed the tool to cater to an even wider range of industries and applications, making it a go-to solution for both simulation and embedded system design.

Industry Applications

VisSim and its successor, solidThinking Embed, are used across various industries where dynamic system modeling and embedded design are essential. Some of the prominent sectors where the software is utilized include:

-

Automotive Industry: In automotive engineering, VisSim is used to model and simulate control systems for engines, transmissions, and other critical subsystems. Engineers can test and validate their models virtually, which reduces the need for costly physical prototypes.

-

Aerospace and Defense: VisSim plays a crucial role in aerospace applications, where it is used to model flight control systems, avionics, and other complex systems that require precise control and performance. The software’s ability to generate C-code for embedded systems is especially valuable for the development of avionics hardware.

-

Energy and Utilities: In the energy sector, VisSim is employed to model power systems, including the control systems for power plants, energy grids, and renewable energy systems. The ability to simulate dynamic behavior in real time is critical for ensuring the stability and efficiency of these systems.

-

Industrial Automation: For industrial control systems, VisSim provides an effective platform for modeling and simulating processes such as factory automation, robotics, and process control. It helps engineers design systems that can be tested and optimized before physical deployment.

-

Medical Devices: In the medical field, VisSim is used to model complex systems in medical devices, such as pacemakers or diagnostic equipment, ensuring that these devices function correctly and meet regulatory standards.

-

Manufacturing: VisSim is utilized in the manufacturing industry to model and optimize manufacturing processes, including those used in automotive, electronics, and other high-precision fields.

Limitations and Considerations

While VisSim is a powerful tool for dynamic system simulation and embedded design, there are some limitations and considerations to keep in mind:

-

Proprietary Software: VisSim is not open-source, which means that users must purchase a license to access its full functionality. This could be a limiting factor for smaller organizations or individuals who do not have the budget for commercial software.

-

Learning Curve: Despite its user-friendly interface, VisSim has a steep learning curve for those unfamiliar with block diagramming or model-based design. New users may need some time to become proficient in using the software effectively.

-

Limited Support for Non-Linear Systems: While VisSim is excellent for modeling linear systems, its capabilities in handling highly non-linear or chaotic systems can be more limited. Users working on such systems may need to seek alternative tools or implement workarounds.

Conclusion

VisSim has established itself as a leading tool in the field of dynamic system simulation and embedded system design. By combining a graphical, block-diagram interface with powerful simulation and code-generation capabilities, VisSim allows engineers to model, simulate, and optimize complex systems with ease. Its use across a wide range of industries—automotive, aerospace, energy, and more—demonstrates its versatility and importance in modern engineering. The transition to solidThinking Embed under Altair’s ownership has only enhanced its capabilities, solidifying its position as a key tool for the next generation of engineers working on embedded systems and dynamic modeling.

With its graphical programming approach and comprehensive toolset, VisSim continues to serve as a crucial resource for engineers seeking to develop and optimize control systems and embedded solutions. Whether designing control systems for vehicles, manufacturing robots, or medical devices, VisSim provides the tools necessary to bring innovative ideas to life.

For more information, visit the official Wikipedia page for VisSim.